Fatigue Life Evaluation

In the mid 90’s, Cargo Carriers of South Africa commissioned BKS Advantech to design a General Freight and Liquid Trailer (GFLT) that was conceptualized to be able to carry either a liquid load in its interior, or a dry load on top of its flat bed. The idea was that a truck would be able to carry a load on any trip it undertook and empty relocations would be unnecessary. At this time, Marco Serra of Engenya was working for BKS Advantech.

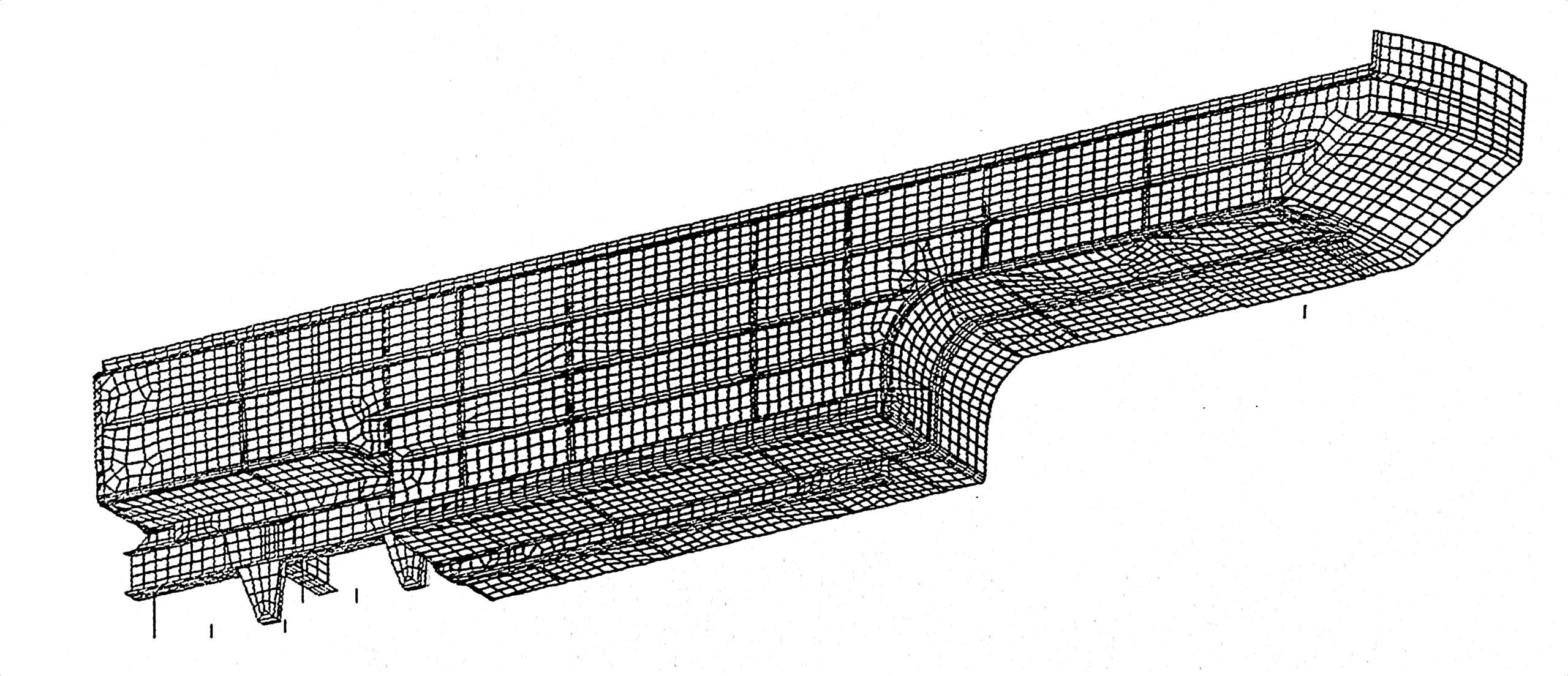

The GFLT was designed entirely in aluminium alloy, which due to its lighter weight meant that a larger payload could be carried. To strengthen the flat-sided structure and to control the dynamics generated by sloshing fluid, the interior of the tank was fitted with a series of baffles and bulkheads. The fact that the centre of gravity was so low was also an advantage for the handling dynamics.

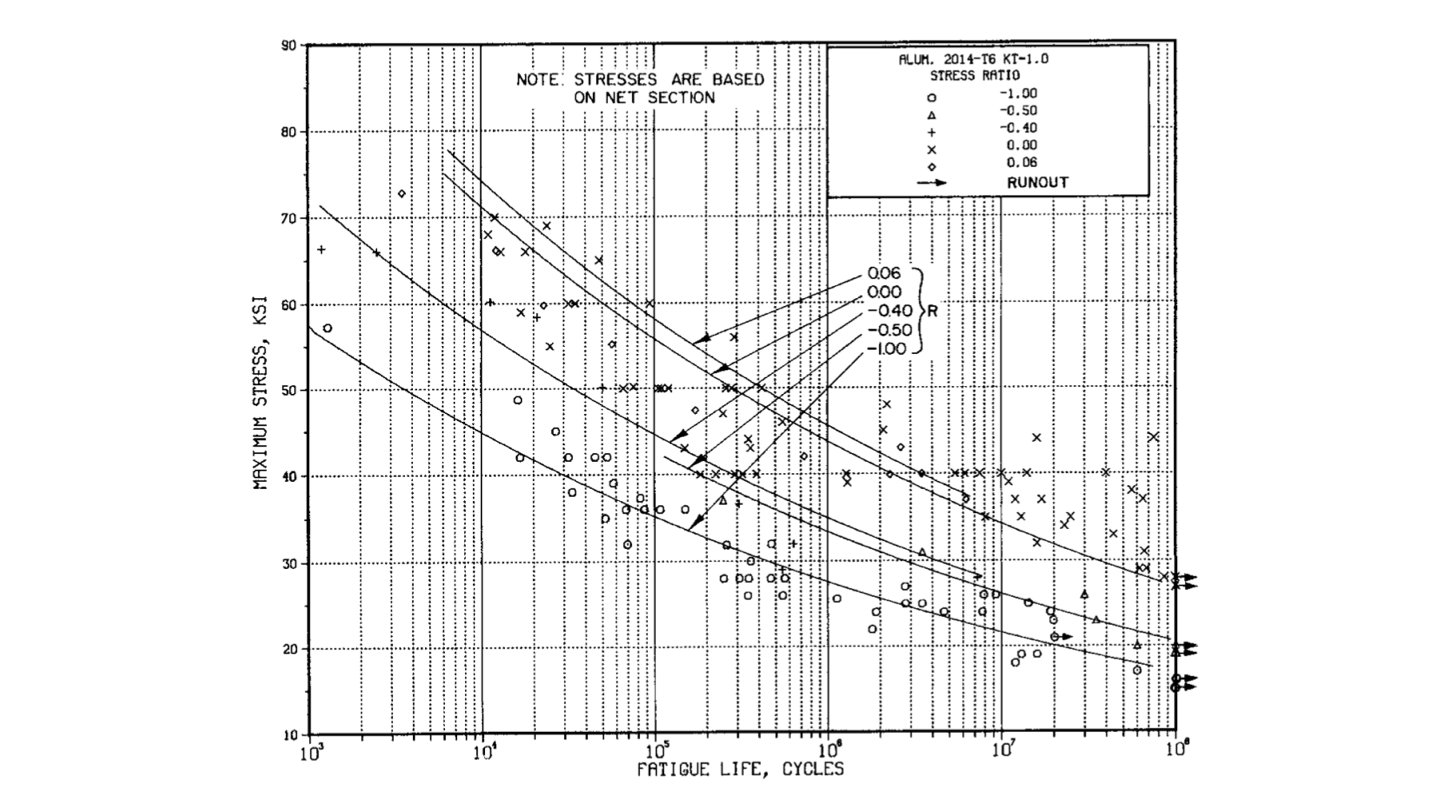

The welded aluminium alloy structure would be subject to cyclical loading due to the presence of cargo, liquid or solid, as well as loads generated while driving on the road. This required the full statistical evaluation of fatigue life over the expected life cycle of the vehicle. These calculations were performed with the aid of finite element analysis for the resolution of stress distributions and intensities. In addition, driving dynamics and dynamic structural loads were investigated through coupled fluid-structure interaction analysis.

It is our understanding that these semi-trailers operated all over Southern Africa up to about 2018.