Concept Development

Concept development and selection is a crucial part of the development process in general, regardless of what is being designed. With the generation of concepts we make the first attempts at turning system requirements and architecture into their practical embodiments. Here are a few examples of projects we have run over the years:

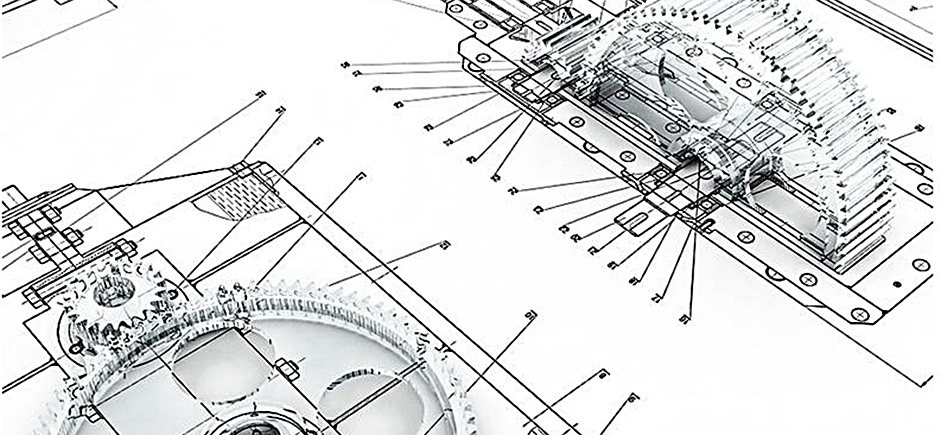

In the context of a product design course with at MIT, the task was to design and build a prototype of a consumer oriented laser level. For this process, a number of methods for requirements definition, generation of technical specifications, concept generation, rating and selection that were taught in the course, had to be applied. The most important lesson was that of ensuring that in selecting the concept to be developed, rating and weighting factors must be thoroughly thought through and understood – in other words, do not follow the process like a recipe but consider its applicability and guidance critically at all times. The novel laser level design seen on the left received an A+.

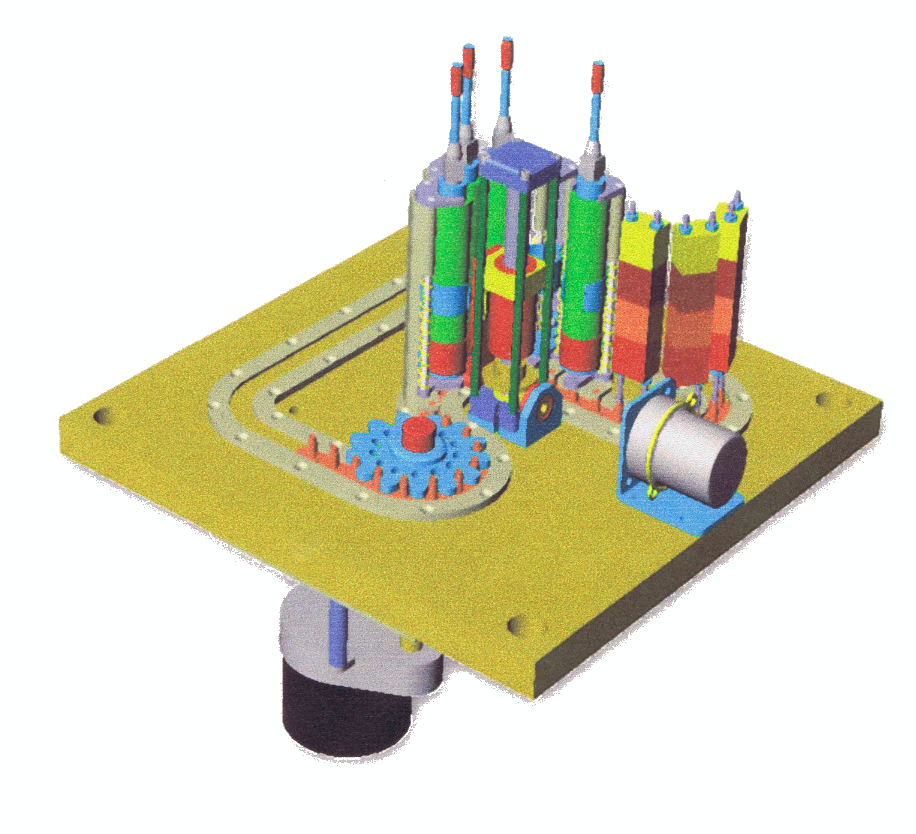

On a more practical note, the materials handling demonstrator pictured in the centre was developed to solve a materials handling problem on a cell culture unit that was being developed for use on the International Space Station. The challenge was to organize and transport dozens of syringe-like containers carrying cell cultures within the very limited space available in the unit. After an extensive study of transport options, inspiration was drawn from airport luggage conveyors to design a conveyance system that only required about 5 mm in height in addition to the height of the containers. This meant that the containment space required could fit well within the available envelope. The demonstrator was built and run to show feasibility of the concept and to address risks associated with potential friction in the design. The demonstrator additionally had the capability of allowing loading and unloading of the specimen vials as well as injecting their contents into the appropriate cell culture chambers. The outcome was the adoption of this concept for design into the unit.

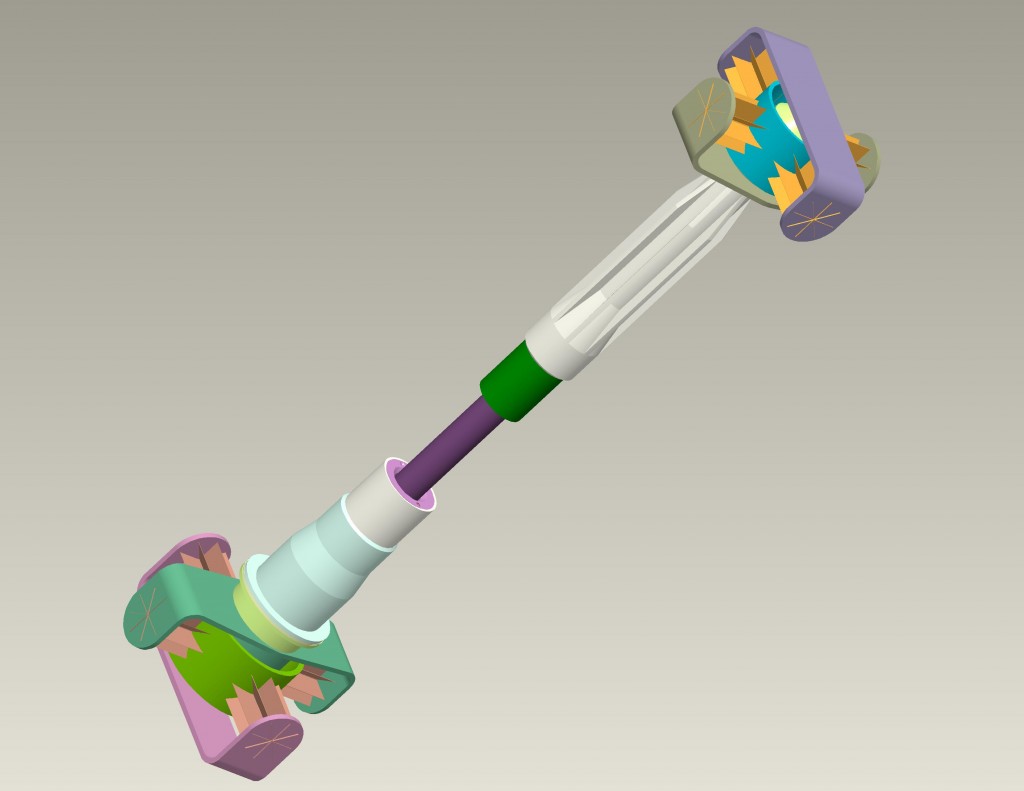

Also in the aerospace realm, the final concept shown represents an actuator designed to be part of a positioning system for the principal mirror in a coronagraph satellite. Since the mirror position had to be picometer accurate, the actuator used flexured joints to completely eliminate the play that is typical of bearings. In addition, it utilized a two stage actuation mechanism with coarse positioning provided by a ballscrew actuator and fine positioning by a piezoelectric actuator. The dynamic characteristics of this concept were verified using finite element analysis.